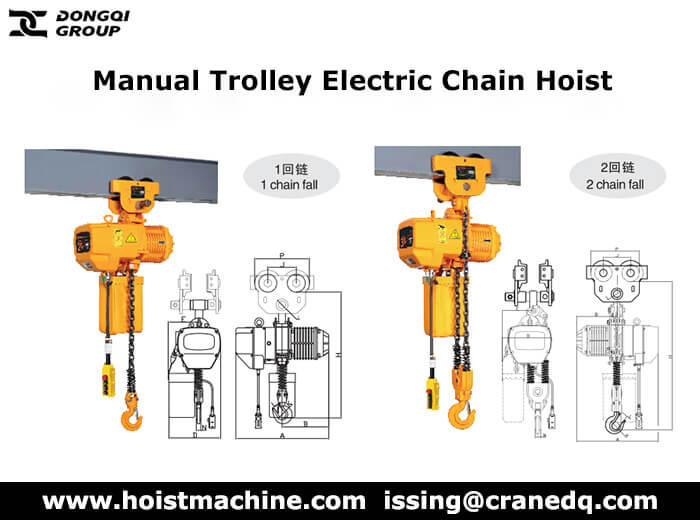

Manual trolley chain hoist is typical of unique optimal structure in shortening the distance between the machine body and the beam tracks, applicable to operations in side low buildings, especially suitable for use in temporarily erected plant buildings.

Manual trolleys are best suited for lighter cost effective jobs. Where as the geared trolley system will move heavy loads easily with a hand chain, the chain transmission brings the power to the wheels; meanwhile the load is balanced on four wheels. Electric chain hoists can be attached to the manual trolley. The hand chains are zinc coated for long life.

Manual trolley chain hoist

Manual Trolley Design Features:

- Robust side plates:

The central load suspension system and the robust side plates go hand in hand to allow for a trolley that can take the demands of a big job. The suspension system works to divide the load evenly among the four wheels. The large forged steel plates enhance tilting protection and will work as cleaners, allowing the trolley to work with minor hindrances on the beam.

- Ball bearings:

The cast iron wheels are quiet and safe due to the lifetime lubricated, sealed ball bearings. Large flange adjustability trolleys are adjustable for various beam sizes by simply changing the number of spacers. The standard bolts are for small flange widths. Longer bolts allow the use on wider flanges like high HE-B-girders with 300 mm widths.

- Precise trolley wheels:

A contour trolley wheel design provides maximum beam contact on flat or tapered beams.

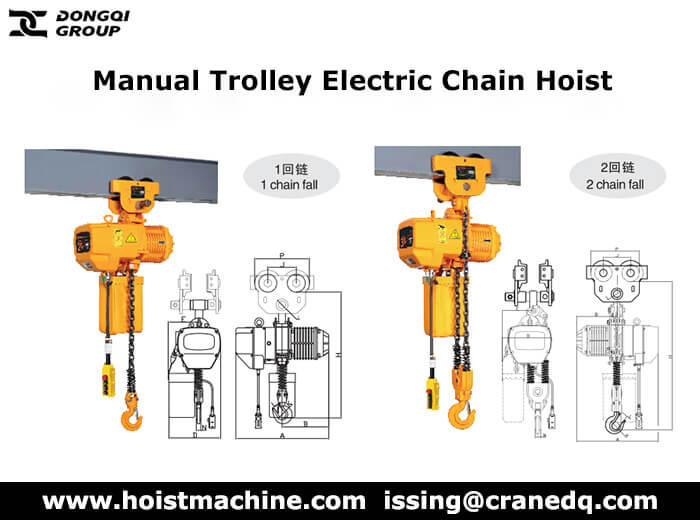

Manual trolley chain hoist for sale

Manual Trolley Chain Hoist for Sale:

- Made of light aluminum alloy,light and hard.the cooling fin is specially designed to ensure heat dissipation with the rate up to 10% and continuous service.

- The integral enclosed structure is applied to place in chemical and electroplate factory.

- The magnetic force generator is the latest design which is featured for generating magnetic force.

- It allows instant brake as soon as the electric power is cut off, thus the braking safety while loading is guaranteed.

- The limit switch device is installed where the weight is lifted on and off to make the motor to stop automatically so as to prohibit the chains from exceeding for safety.

- The chain imported FEC80 ultra heat-treatable aluminum alloy chain, it can be safely used in poor environment such as rain, sea water and chemicals.

- It it hot forged with perfect strength that it is hard to break.the operation safety of the lower hook is ensured by its 360 degrees rotation and safety tongue piece.

- The loading support frame consists of two steel plates, which is extremely sturdy.

- 24v/36v transformer device, this device is used to prohibit unexpected accidents caused by electric leakage and guarantees the safe use while raining.